- Personal attention

- Fast delivery

- In house technical service

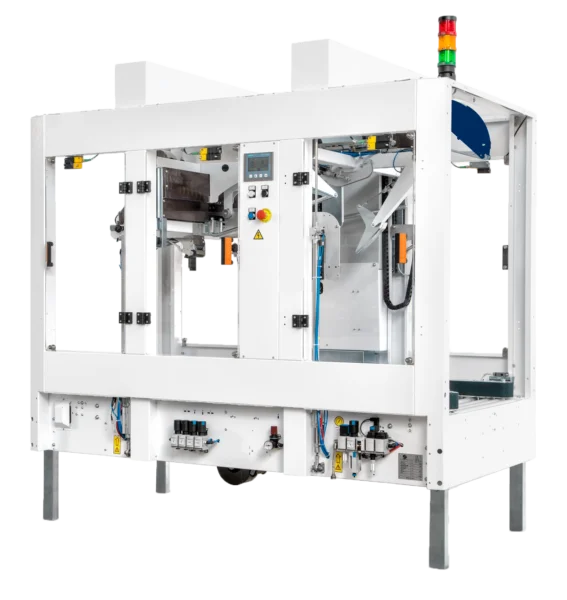

Automatic Tape Machine for Packaging

Our tape machines come in various sizes and configurations to suit your packaging needs. Depending on your requirements, we offer both semi-automatic and fully automatic solutions.

A semi-automatic tape machine is ideal for closing series of boxes of the same size. It can be manually adjusted to the desired format, although this process can be less convenient when dealing with frequent format changes. On the other hand, an automatic tape machine performs the same function but is capable of handling boxes of various sizes mixed together. With a fully automatic tape machine, no operator intervention is required as the machine operates entirely on its own.

Below, you'll find an overview of our automatic tape machines.

To receive more information? Complete the form below.

Automatic Tape Machine for Packaging

Our tape machines come in various sizes and configurations to suit your packaging needs. Depending on your requirements, we offer both semi-automatic and fully automatic solutions.

A semi-automatic tape machine is ideal for closing series of boxes of the same size. It can be manually adjusted to the desired format, although this process can be less convenient when dealing with frequent format changes. On the other hand, an automatic tape machine performs the same function but is capable of handling boxes of various sizes mixed together. With a fully automatic tape machine, no operator intervention is required as the machine operates entirely on its own.

Below, you'll find an overview of our automatic tape machines.

To receive more information? Complete the form below.

(Fully) automatic tape machines

A specialised piece of machinery known as an automatic tape machine is used in the packaging business to efficiently and automatically apply adhesive tape to cartons, packages, or boxes during the packaging and sealing process. High-volume packaging companies frequently use these devices to increase consistency and efficiency. They can apply and dispense tape smoothly, securing items with consistent seals. Automatic tape machines are available in a variety of configurations, ranging from table top units for smaller operations to high-speed, fully automated systems for large-scale packing plants. This gives businesses the flexibility to select the model that best suits their unique requirements.

- High-Speed Operation- Rapid and continuous tape application is made possible by automatic tape machines, which also considerably increase packaging efficiency and throughput in high-volume processes.

- Precision and Consistency- These devices apply tape with accuracy and consistency, guaranteeing reliable product packing and sealing.

- Adjustable Settings- Numerous automatic tape machines have changeable tape length, tension, and cutting settings that enable customisation to fit unique packaging needs.

- Safety Features- These devices frequently have safety features to safeguard the users, like emergency stop buttons and sensors that halt operation when an impediment is detected.

- Durability and Reliability- Automatic tape machines feature tough construction and sturdy components for long-lasting and dependable performance in demanding packing applications. They are designed to endure the rigours of industrial operation.

- Production Volume- Consider your packaging needs in terms of volume and timeliness. Select a machine that can handle your production needs. Choose a machine with faster tape application capabilities for high-volume tasks.

- Tape Type and Size- Consider the type and size of the tape you plan to use. Make sure the machine can handle the particular tape dimensions and materials needed for your packaging applications.

- Automation Level- Identify the level of automation you require. Some tape dispensers are totally automatic and may integrate with your production line for seamless tape application, while others are fully automatic and require human box loading.

- Adjustability and Customization- For machines that can accept different box sizes and packaging designs, look for features that can be adjusted, such as tape length, tension control, and cutting options. This adaptability can increase productivity and decrease material waste.

- Maintenance and Support- Examine how simple maintenance is and whether spare parts and technical help are readily available. In your packing operations, a dependable and well-supported machine will reduce downtime and guarantee long-term performance.