Features of Strapping Machine: -

A typical strapping machine has the following essential characteristics:

- Automatic Operation:Strapping machines offer quick, convenient, and mostly automatic operation, reducing labor and saving time in securing shipments or goods.

- Adjustable Tension Control:Strapping machines offer adjustable tension for secure and customized strapping, ensuring optimal fit and maximum safety for boxed goods.

- Multiple Strapping options:Strapping machines offer versatile packaging solutions with multiple strapping options, accommodating various materials, widths, and thicknesses for diverse industries and applications.

- Safety featuresSafety features in strapping machines, such as emergency stop buttons, sensors, and protective enclosures, ensure user and product safety during the strapping process.

- Increased Productivity and Efficiency:Automating the strapping process with machines improves productivity and efficiency by saving time and effort in securing packages.

- Enhanced Load Stability and Protection:Strapping machines provide tight and secure strapping to enhance load stability and protection during storage or transportation, preventing shifting, tipping, or damage, making them essential for bulk shipments and delicate items.

- Cost Savings:Automating strapping process with a machine reduces labor costs, minimizes waste, enhances load stability, and prevents product damage, resulting in long-term financial benefits.

- Versatility and Customization:Strapping machines offer adaptability and customization for handling diverse package sizes, shapes, and materials, making them essential across industries such as transportation, manufacturing, distribution, and e-commerce.

- Semi-automatic Strapping MachineIn businesses where moderate to high volumes of packages or items need to be strapped, semi-automatic strapping devices are frequently utilized to use these machines, some physical action is needed, such as wrapping the strap around the box and starting the strapping procedure. The machine automatically tightens, seals, and cuts the strap when the user starts the strapping cycle, resulting in reliable and secure strapping. Semi-automatic equipment can work with a variety of strap sizes and materials, including plastic and steel, and is adaptable.

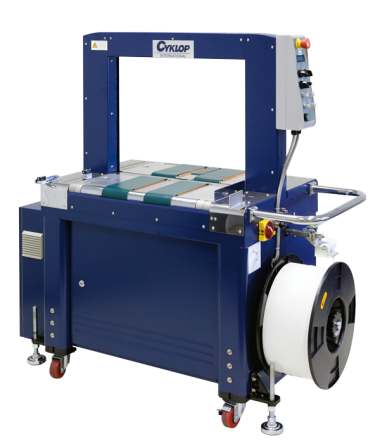

- Automatic Strapping MachineAutomatic strapping equipment is made for high-volume production lines where a lot of packages or goods need to be fastened securely. These machines have cutting-edge features that eliminate user intervention, such as automatic strap feeding, tensioning, sealing, and cutting. They have sensors and controls that guarantee accurate and consistent strapping, lowering the possibility of mistakes or irregularities. Conveyor systems and other automated packing lines can incorporate automatic machinery to streamline the strapping procedure and boost output.

- Pallet-Strapping Machine:In warehouses, distribution centers, and logistics operations, pallet strapping machines are frequently used to secure and stabilize pallet loads. These devices can wrap the pallet with several straps at once for the best load retention and to stop it from shifting during storage or transportation. High-tensile plastic or polyester straps, which provide good strength and stability while being reasonably priced and secure to handle, are frequently used by pallet strapping machines. Hey, are appropriate for varied pallet sizes and configurations since they have features like adjustable tension, programmed strapping patterns, and automatic feeding.

- Fast and Effective Operation:Strapping machines are made to fast and effective strap packages or products. They can quickly fasten straps around objects, cutting down on the time needed for manual strapping.

- Adjustable Tension and Strap Size:Adjustable tension settings and the ability to accommodate varying strap sizes make these machines versatile for diverse packing needs, allowing customers to regulate strap tightness based on package requirements.

- Reliable and Secure Strapping:Strapping machines provide dependable and secure strapping, ensuring stability and preventing package breakage during transit.

- Automated and User-Friendly:Automated, user-friendly strapping machines with intuitive controls, built-in sensors, and timers streamline the process, boost productivity, and accommodate users of all experience levels.

- Strapping requirements: When selecting a strapping machine, consider the items' characteristics, package size and weight, and required tension strength, as different machines accommodate various strap types, widths, and tensions.

- Production volume: Consider the production volume to determine the appropriate strapping machine, opting for quicker cycles or automation for high volumes and simpler/manual machines for modest volumes.

- Machine specifications and features:Choosing a strapping machine requires considering its speed, efficiency, ease of use and upkeep, longevity, compatibility with current packing line, and future expansion capabilities.

Contact us

INDIA Quotation

What is strapping?

Strapping is the process of applying a steel or plastic strap around a product or pallet to bundle, reinforce, or attach it to something. This is done using a strapping machine (banding machine) or strapping tool. Strapping machines can be divided into semi-automatic strapping machines, (fully) automatic strapping machines and pallet strapping machines. Strapping tools can be divided into hand strapping tools and battery & pneumatic strapping tools.

The purpose of strapping products is to transport and / or store them quickly and undamaged in an efficient and safe manner.

How does strapping work?

The strapping band is applied horizontally or vertically around the product, with the ends of the strapping material coming together. A strapping tool or strapping machine connects these ends after the correct tension has been applied. A strapping tool or strapping machine closes the strapping band using a seal or buckle, or by welding the ends together. After this, the excess strapping band is cut automatically.

All materials, sizes and shapes can be strapped.

Applications of strapping

Examples of concrete applications of strapping are:

- Closing boxes and shipping containers

- Bundling for handling and shipping: e.g., newspapers, pipes, wood or concrete blocks

- Attaching or securing products to pallets and crates

- Reinforce wooden boxes, cardboard boxes and crates

- Attach items to flat wagons or flatbed trailers

- Securing a unit load such as bricks or flat glass

- Keep rolls of steel or paper together

- Lifting assistance with for example roof tiles or newspapers

- Theft protection: it can be seen immediately if the strapping band has been removed

Which type of strapping material is most suitable?

There are many facets that determine which kind of strapping material is most suitable. The choice of PP strap, PET or steel strap is essential. What width and thickness should the material have? Do you want manual or machine strapping? The right choice depends on several factors, such as:

- Is the load stable or unstable?

- How heavy is the load?

- Does the load deform?

- How long are the products stored?

- How long does the transport of the products take?

- How often are the products loaded and unloaded?

- Are the products fragile or is there a risk of damage?

- Where is it stored? Environmental factors play a role in this

- Is the material applied mechanically or manually?

- What is the requested capacity in numbers per day?

- Where is the strapping done? Is this a permanent place or is flexibility important?

These points are of course also important when choosing the right strapping machine or strapping tool. Making the right choice, considering the best solution for you, is complex and requires experience. We would be happy to advise you on this, without any obligation. Contact us!

Consumables

Polypropylene (PP strap), polyester (PET strap) and steel strap are the most commonly used straps. Each variety has unique properties, is suitable for different areas of application and has advantages and disadvantages.

Steel strap is designed for extreme tasks that require heavy or very strong strapping. Steel strap is ideal if high strength and minimal elongation is desired, or if the product gets hot or can be sharp.

Polypropylene strap is the most commonly used strapping material and is used in a wide variety of industries. A light or medium load can easily be strapped with PP strap. PP strap is excellent under normal circumstances.

Polyester strap is the strongest type of plastic strap. This strapping band is often used under heavy loads that require high tension. Because PET strapping is so strong, it is used in many industries as an alternative to steel strapping.

Advice

Would you like tailor-made advice or would you like more information about which type of belt or device is most suitable for you?

From the simplest handheld device to large project installations, our experts are ready to give you good advice. Feel free to contact us!