- Personal attention

- Fast delivery

- In house technical service

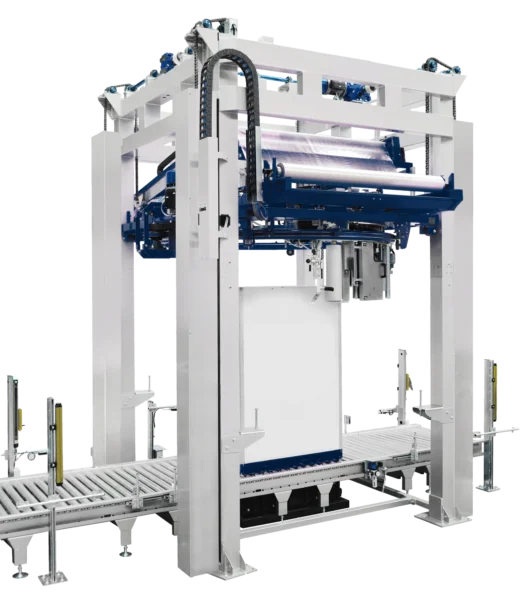

Ring Stretch Wrapper Machine

A ring stretch wrapper functions on a concept akin to an arm wrapper, in which the load remains in place as the film carriage encircles the pallet. However, unlike an arm wrapper, the film carriage in a ring wrapper is mounted on or within a large ring, not on an arm.

This configuration allows the film carriage to spin at much higher speeds, significantly increasing the wrapping capacity per hour. Ideal for handling large (peak) volumes that demand rapid wrapping, a ring wrapper can accommodate up to 180 pallets per hour.

Below you will find a comprehensive list of our ring stretch wrapper models.

For more information or to request further assistance, please fill out the form below!

Ring Stretch Wrapper Machine

A ring stretch wrapper functions on a concept akin to an arm wrapper, in which the load remains in place as the film carriage encircles the pallet. However, unlike an arm wrapper, the film carriage in a ring wrapper is mounted on or within a large ring, not on an arm.

This configuration allows the film carriage to spin at much higher speeds, significantly increasing the wrapping capacity per hour. Ideal for handling large (peak) volumes that demand rapid wrapping, a ring wrapper can accommodate up to 180 pallets per hour.

Below you will find a comprehensive list of our ring stretch wrapper models.

For more information or to request further assistance, please fill out the form below!

What is Ring Stretch Wrapper Machine

A ring stretch wrapper machine is a cutting-edge piece of packing equipment that is used by packaging businesses to quickly and effectively stretch-wrap palletized cargoes. For the purpose of stabilising and safeguarding goods during travel and storage, this machine works by enclosing the load with the film as it rotates on a spinning ring. It is an essential tool for optimising packaging processes in the business since it increases packaging efficiency, reduces film waste, and maintains uniformity in packaging quality.

- Efficient and Consistent Packaging:Packaging that is Efficient and Consistent: Ring stretch wrapper machines provide a very effective and reliable way to package goods. They are made to swiftly and evenly apply stretch film to pallets or loads, ensuring that each box is safely wrapped for storage and transportation.

- Cost-Effective: Using a ring stretch wrapper machine has a number of important financial benefits. Stretch film waste can be reduced by operating these machines more effectively. In addition to lowering material costs, this promotes sustainability.

- Versatile Wrapping Options:Ring stretch wrappers offer a variety of packaging alternatives for flexible wrapping. Depending on the precise packaging needs, they can wrap pallets in a variety of ways, including spiral wraps, cross wraps, and more. They are appropriate for a variety of sectors and product kinds due to their versatility.

- Increased Productivity:Ring stretch wrapper machines are made to automate the wrapping process, which lowers the demand for manual labour and increases productivity. As more loads can be wrapped in less time, productivity rises, enabling your packaging business to fulfil busy production schedules.

- Enhanced Load Stability: During the wrapping process, ring stretch wrappers impart continuous strain to the stretch film, which enhances load stability. This guarantees that goods are packaged safely, lowering the possibility of damage during delivery and cutting down on the possibility of pricey returns or replacements.

- Efficiency and Speed: High-speed wrapping is a speciality of ring stretch wrapper machines. They can effectively package pallets of all shapes and sizes, guaranteeing that your packing procedure is quick and effective. greater productivity and lower labour expenses may result from this greater efficiency.

- Versatility:These devices are adaptable and can deal with a variety of packaging needs. They can be adapted to a variety of product lines because they may be used to wrap both light and heavy loads. Different types of films and wrapping techniques can be employed thanks to adjustable tension control.

- Film Savings:Ring stretch wrappers are made to maximise the use of film, saving money on film. They need less stretch film to secure a load since they apply it tightly and consistently. By reducing waste, this not only reduces material costs but also helps with ecological initiatives.

- Consistency and Load Stability: Ring wrappers guarantee regular, consistent wrapping, which enhances the stability of the load during storage and transportation. This lowers the possibility of damaged items and aids in maintaining product integrity, both of which are essential for retaining customers and lowering return rates.

- Friendly User Interfaces and Automation functions:Modern ring stretch wrapper machines have user-friendly interfaces and automation functions. As a result, they are simple to use and require little training for your packaging staff. Many models also provide remote monitoring and diagnostic features, which increase the effectiveness of maintenance.

- Pallet Wrapping: Ring stretch wrapper machines are excellent in stabilising loads on pallets when wrapping them. Stretch film can be effectively wrapped around products that have been palletized, ensuring stability during travel and lowering the possibility of damage. For sectors like distribution, warehousing, and logistics, this application is essential.

- Improved Load Stability: Ring stretch wrappers give users fine-grained control over the tension and wrapping pattern of stretch film. This improves load stability and reduces product moving while being transported. This is especially advantageous for sectors that deal with goods that are delicate or have odd shapes.

- Cost savings:The amount of stretch film needed for each pallet load can be greatly decreased with the use of ring stretch wrappers. Companies can reduce the cost of packing materials by maximising film usage and reducing waste. Additionally, the regular pattern of wrapping lowers the possibility of damage claims, potentially saving money.

- Increased Productivity: Productivity is increased as a result of these machines' quick and effective pallet wrapping. They automate the wrapping procedure so that staff can concentrate on other responsibilities. The ring stretch wrapper can also be fully automated, allowing for easy integration with production lines.

- Food and Beverage Industry

- Pharmaceutical Industry

- Manufacturing and Automotive Industry

- E-commerce and Retail Distribution

- Building Materials Industry

- Size and Type of the Load:Consider the variety of goods you must wrap. Take into account the range in the dimensions, forms, and weights of your loads. The Ring Stretch Wrapper should be able to manage the biggest and heaviest loads you regularly handle. While certain machines may be better suited for wrapping ordinary pallets, others may be better suited for products of unusual shapes.

- Production volume:Calculate the projected growth and amount of production for your business. If your throughput is continuously high, a high-capacity machine might be required. On the other hand, a smaller machine can be enough for lower output rates. To achieve your production objectives, it's also critical to take the machine's speed and efficiency into account.

- Film compatibility: Stretch films come in a variety of qualities and thicknesses. Make sure the stretch film types you employ are compatible with the Ring Stretch Wrapper. Some machines could be flexible in their film choices or tailored for a certain genre of film. To accomplish optimal load containment and minimise film waste, compatibility is essential.

- Automation and Control Features:Modern Ring Stretch Wrapper Machines are equipped with a variety of automation and control functions. Think about the degree of automation you require, such as automatic film application, programmable wrapping programmes, adjustable tension control, etc. Controls and diagnostics that are easy to use can increase productivity and decrease operator error.

- Space and Installation Requirements:Consider the machine's installation requirements as well as the space that is available in your business. Ring stretch wrappers can have various footprints and may need particular floor space and power sources. Make sure the machine will fit in your space and that it conforms with safety requirements.