- Personal attention

- Fast delivery

- In house technical service

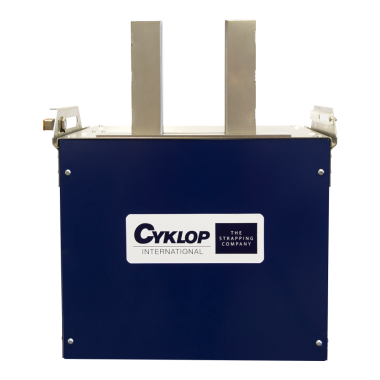

Fully Automatic Bundling Elastobinder

Our Fully Automatic Bundling Elastobinder is designed for seamless bundling using preformed plastic bands.

Specifically engineered for the automated bundling of lightweight products with elastic bands, such as the Strepper®, this Elastobinder offers numerous advantages. Its bundling method ensures a closed form without knots, preventing deformation and damage to the products. Additionally, with one size of Strepper®, both large and small products can be efficiently bundled.

The Elastobinder® is versatile, capable of bundling products horizontally or vertically. Product loading and unloading can be done manually or facilitated by conveyor belts or turntables.

For further information, please refer to the overview of our Elastobinders below.

If you require additional details, kindly complete the form provided below!

Fully Automatic Bundling Elastobinder

Our Fully Automatic Bundling Elastobinder is designed for seamless bundling using preformed plastic bands.

Specifically engineered for the automated bundling of lightweight products with elastic bands, such as the Strepper®, this Elastobinder offers numerous advantages. Its bundling method ensures a closed form without knots, preventing deformation and damage to the products. Additionally, with one size of Strepper®, both large and small products can be efficiently bundled.

The Elastobinder® is versatile, capable of bundling products horizontally or vertically. Product loading and unloading can be done manually or facilitated by conveyor belts or turntables.

For further information, please refer to the overview of our Elastobinders below.

If you require additional details, kindly complete the form provided below!

What is Fully Automatic Bundling Elastobinder?

In the packaging sector, a Fully Automatic Bundling Elastobinder is a cutting-edge and effective automated system for safely bundling and packing products. By automating the application of elastic cord binders (Elastobinders) to items, this state-of-the-art technology reduces the need for manual labour and boosts production effectiveness. The Fully Automatic Bundling Elastobinder is perfect for companies with high-volume packaging requirements since it is fitted with swift and precise mechanisms that can handle a variety of product sizes and shapes.

- Product Feeding- The Fully Automatic Bundling Elastobinder system is fed with the products that will be packaged. Operators can accomplish this manually, or it can be automated and connected with a conveyor system.

- Product Positioning- The products are precisely positioned by the system before bundling. It is capable of handling a range of product sizes and shapes depending on the design and specifications.

- Elastobinder Application- Elastic Cord Binders (Elastobinders) may be applied automatically, which is the system's core functionality. The elastic cord is dispensed by the machine, stretched to the required tension, and then tightly wrapped around the goods. A tension control that is adjustable makes sure that the bundling is accurate and complies with all packing regulations.

- Cutting and Sealing- The technique cuts and seals the elastic cable once it has been tightly wrapped around the products, resulting in a bundle that is both compact and tamper-evident.

- Product Discharge- The packaged goods are subsequently removed from the device and prepared for handling, labelling, or shipping.

- Monitoring and Control- Fully Automatic Bundling by Elastobinder frequently includes an intuitive control panel that enables users to keep an eye on the process, change parameters, and troubleshoot as needed.

- Safety Features- To safeguard operators and prevent mishaps while in use, advanced safety features are frequently incorporated into the system.

- Automated Operation- This technique ensures uniform and effective bundling of products without requiring a lot of physical labour.

- · Versatility- It is appropriate for a variety of industries and applications since it can handle a wide range of product sizes and shapes.

- Adjustable Tension Control- The machine's tension control is adjustable, enabling fine customization of the bundling tightness to satisfy certain packaging needs.

- High-Speed Performance- High speed operation of the elastobinder considerably boosts production throughput and efficiency.

- Tamper-Evident Sealing- In order to improve product safety and integrity during transit and storage, it produces safe and tamper-evident bundles.

- User-Friendly Interface- The system often has an easy-to-use control panel for monitoring and operation, which makes installation and troubleshooting simpler.

- Automation- Bundling that is fully automatic has automated processes in place, less manual labour is required and uniform, error-free bundling is guaranteed.

- Versatility- It is appropriate for numerous sectors and packaging applications since it is adaptable enough to handle a wide variety of product sizes, shapes, and materials.

- Customizable Tension Control- With the system's changeable tension control, bundling tightness may be precisely customised to fulfil various packaging needs.

- High-Speed Performance- It operates at fast speeds, greatly enhancing throughput and manufacturing efficiency, saving time and resources.

- Tamper-Evident Sealing- Bundling that is fully automatic Enhancing product security and guaranteeing the integrity of bundled objects throughout transit and storage, Elastobinder generates safe and tamper-evident bundles.

- User-Friendly Interface- It typically has user-friendly controls and an intuitive interface, which makes installation, monitoring, and maintenance easier.

- Reliability- It is designed to be dependable and long-lasting, providing enduring performance in challenging packing settings.