- Personal attention

- Fast delivery

- In house technical service

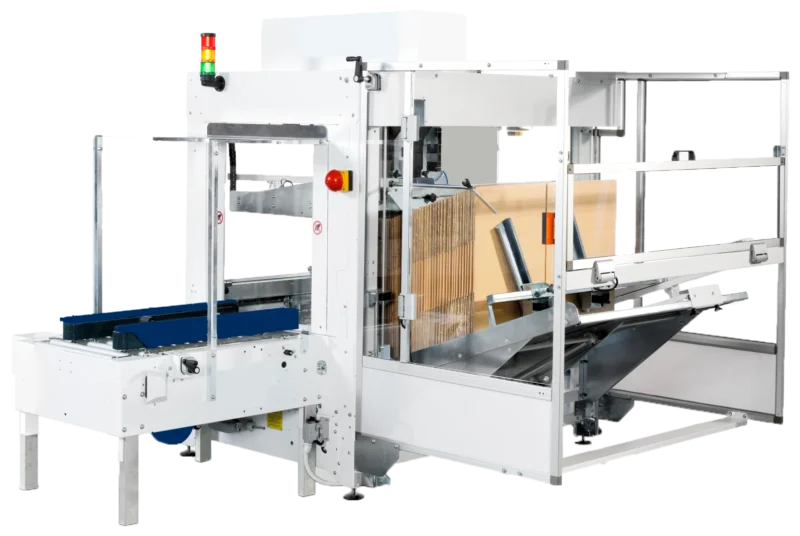

Carton erecting machines

When dealing with large quantities of boxes, opting for an automatic carton erecting machine proves to be a wise choice.

An automatic box erector, within the category of carton erecting machines, retrieves an empty box from the warehouse, unfolds it, and folds the bottom flaps of the box. Subsequently, the bottom of the box is sealed with tape before being transported to the filling line. Whether operating independently or as part of a packaging line, a carton erecting machine ensures smooth and efficient workflow.

Below, you'll find an overview of our carton erecting machines.

Would you like to receive additional information? Please proceed to fill out the form located below!

Carton erecting machines

When dealing with large quantities of boxes, opting for an automatic carton erecting machine proves to be a wise choice.

An automatic box erector, within the category of carton erecting machines, retrieves an empty box from the warehouse, unfolds it, and folds the bottom flaps of the box. Subsequently, the bottom of the box is sealed with tape before being transported to the filling line. Whether operating independently or as part of a packaging line, a carton erecting machine ensures smooth and efficient workflow.

Below, you'll find an overview of our carton erecting machines.

Would you like to receive additional information? Please proceed to fill out the form located below!

What is a Carton Erecting machine?

A specialised piece of equipment called a carton erecting machine is used in the packaging business to automate the process of manufacturing and erecting cardboard boxes or cartons. The efficiency of packaging processes is greatly improved by using these machines to turn flat cardboard blanks into ready-to-use cartons. In industries including food and beverage, pharmaceuticals, and consumer goods, where products need to be efficiently packed into cartons for transit and retail display, carton erecting machines are frequently used. They can handle multiple carton sizes and types, exist in a variety of configurations ranging from semi-automated to fully automatic versions, and are an invaluable asset for companies wishing to automate their packing procedures.

- Automatic Carton Formation- These devices automate the assembly and shaping of flat cardboard blanks into cartons, doing away with the need for manual labour and assuring uniform carton quality.

- Adjustability- Carton erecting machines are adaptable for diverse packaging needs since they frequently include customizable settings to fit different carton sizes and shapes.

- High-Speed Operation- They are built for efficiency and can move at high rates, enabling quick carton manufacturing to satisfy the needs of production lines with high throughput.

- User-Friendly Controls- Many machines have simple controls and touchscreens for quick setup and operation, minimising downtime and improving packing procedures.

- Automated Operation- The automated and semi-automated functioning of carton erecting machines reduces the demand for manual labour during the carton assembling process and boosts production effectiveness.

- Versatility- These devices can handle a range of carton shapes and sizes, making them appropriate for various product dimensions and packaging needs.

- Precision and Consistency- By precisely and consistently folding, sealing, and glueing cartons, carton erecting machines guarantee uniform carton quality and packaging presentation.

- Quick Changeover- Many of these machines have quick changeover capabilities, which increase operational flexibility and efficiency by enabling packaging professionals to convert between various carton sizes and types with little downtime.