- Personal attention

- Fast delivery

- In house technical service

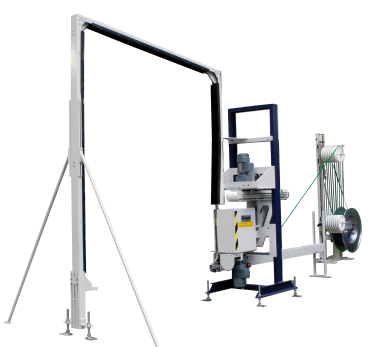

Fully Automatic Strapping Machines

Discover a range of strapping machines from Cyklop designed to meet various needs. Ideal for handling large volumes, our (fully) automatic machines can be tailored to suit your specific requirements.

Benefits of using these machines include speed, efficiency, and automation. No need for seals, and they can seamlessly integrate into assembly lines or transport systems. You can also easily adjust the voltage according to your needs.

Explore our (fully) automatic strapping machines below. Interested in more details?

Complete the form, and we'll give you the details you're looking for. Plus, inquire about our fully automatic strapping machine prices. Streamline your strapping process with Cyklop's cutting-edge solutions.

Fully Automatic Strapping Machines

Discover a range of strapping machines from Cyklop designed to meet various needs. Ideal for handling large volumes, our (fully) automatic machines can be tailored to suit your specific requirements.

Benefits of using these machines include speed, efficiency, and automation. No need for seals, and they can seamlessly integrate into assembly lines or transport systems. You can also easily adjust the voltage according to your needs.

Explore our (fully) automatic strapping machines below. Interested in more details?

Complete the form, and we'll give you the details you're looking for. Plus, inquire about our fully automatic strapping machine prices. Streamline your strapping process with Cyklop's cutting-edge solutions.

What is Fully Automatic Strapping Machine?

In order to streamline and automate the strapping or bundling of goods and packages, packaging businesses employ Fully Automatic Strapping Machines. This cutting-edge equipment effectively fastens products with plastic or steel straps, assuring uniform tension, dependability, and speed in the packaging process, eventually boosting productivity and overall packaging quality.

- Operation Efficiency:Fully automatic strapping machines are made to make packaging easier. In order to increase total package efficiency and decrease the need for manual labour, they can automatically feed, tension, seal, and cut strapping materials.

- Versatility: These devices can easily adjust to different packing requirements. They can be set up for a variety of package sizes and shapes and can accommodate various strapping materials, such as steel or polypropylene.

- Consistency and Precision:Fully automatic strapping machines make sure that strapping placement and tensioning are constant and accurate, reducing the danger of products being damaged during shipping. Additionally, improving the overall look of packed items is this consistency.

- User-Friendly Controls:The majority of contemporary fully automatic strapping machines have settings and controls that are user-friendly, making them simple to use and modify. Operators can quickly alter the strapping parameters to satisfy certain packaging needs.

- Production Gains and Cost Savings:These machines greatly boost packaging production by automating the strapping procedure. They lessen the need for physical labour, lower the possibility of strapping mistakes, and ultimately result in cost savings due to increased operational effectiveness.

- Enhanced Efficiency: The productivity of a packaging company is greatly increased by fully automatic strapping devices. These devices can quickly and consistently strap packages, cutting down on the time and labour needed for the strapping operation. A better throughput of packaged items and cost reductions are both results of this efficiency.

- Increased Consistency:Automatic strapping machines offer uniform and consistent strapping tension, guaranteeing that each package is tightly and consistently fastened. This consistency reduces the possibility of damage occurring during transportation, which can be a problem with manual strapping.

- Reduced Labour Costs:You can use less manual labour by automating the strapping procedure. This reduces labour expenses while also freeing up your personnel to engage on higher-value duties like quality assurance or packaging modification.

- Enhanced Safety: Safety elements are built into fully automatic strapping devices to shield users from potential harm. The workplace is safer for your employees thanks to the sensors and controls that are frequently built into these devices.

- Customization and Flexibility:Flexibility and customization options are available on many contemporary fully automatic strapping machines, including the capacity to handle varied package shapes and sizes, multiple strapping patterns, and adjustable strap tension. Due to its adaptability, the device can meet a variety of packaging requirements and handle a wide range of products.

- Efficiency and Speed: Fully automatic strapping machines are made to strap packages quickly and effectively. They can quickly increase your packaging throughput by strapping several products at once.

- Consistency: By providing consistent and uniform strapping tension, these machines make sure that every item is safely fastened without running the risk of over- or under-tightening, which can harm products.

- User-Friendly Operation:Fully automatic strapping devices have an intuitive design and are simple to use. They frequently have simple controls, so your packaging staff can set up and maintain the equipment with little instruction.

- Customization:You may adjust strapping parameters like tension, sealing duration, and strap width on many fully automatic strapping machines to fit the unique needs of your products and packaging materials.

- Reliability and Durability:These devices are designed to resist continuous, strenuous packaging operations. They are made of durable materials and require little upkeep, offering a lengthy service life and less downtime for your packing operation.

- Strapping Material Compatibility:Check that the strapping machine is compatible with the kind and size of strapping material you typically use, such as steel or polypropylene straps. To prevent compatibility problems, make sure the machine can accommodate the width and thickness of the straps you want to use

- Production Volume: Calculate the daily or hourly production volume for your packaging company. Choose a strapping machine that has a throughput capacity that meets or exceeds your needs. To increase efficiency and decrease downtime, look for features like high-speed strapping and automated tension adjustments.

- Automation Features:Consider the machine's level of automation. In terms of characteristics like auto-feed, tensioning, sealing, and ejection of strapped goods, fully automatic strapping machines can differ. To reduce manual intervention and labour expenses, pick a machine with automation features that are compatible with your packing process.

- Machine Durability and Reliability:Strapping machines are reliable and withstand continuous usage in a packing environment. Give high priority to equipment made by renowned companies with a track record for dependability and durability. To ensure long-term performance, look for qualities like heavy-duty construction, strong motors, and little maintenance needed.

- Safety and Usability: Employee safety and usability are of utmost importance. Make sure the strapping machine you choose complies with safety regulations and is equipped with safety features like emergency stop buttons and protective coverings. To cut down on staff training time, choose a machine with user-friendly controls, clear instructions, and minimal learning curves.