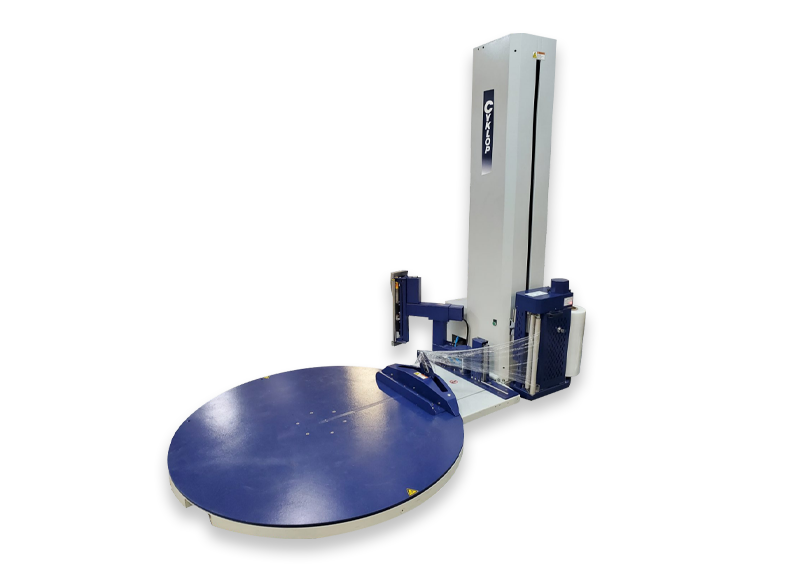

Stretch Wrapper CST 205 AUTO

CST 205 is an advanced pallet wrapping machine designed to streamline and automate packaging processes. Operators effortlessly load pallets onto the turntable and initiate the wrapping cycle using a remote control or touch panel. Once the cycle is complete, the machine autonomously cuts the film and ensures a clean finish by wiping the tail-end against the load. Notably, the film gripper keeps the film securely connected, ready for the next pack, while the entire wrapping cycle operates seamlessly in automatic mode, boosting productivity. Although pallet unloading remains a manual task, CST 205 boasts user-friendly controls for easy adjustment of program parameters and settings via its new display. This versatility extends to manual operation of various functions, such as film patterns and tension. Moreover, the machine maintains a consistent pre-stretch ratio, guaranteeing minimal film consumption and cost efficiency load after load.

| Technical Specifications: | |

|---|---|

| Table diam | 01650 mm |

| Speed | 12rpm |

| Capacity | 10-25 pallets/hour (base on pallet height and turns to be wrapped) |

| Start/stop | Frequency controlled |

| Bottom/Top wraps | 1-9 |

| Film carriage speed | Variable speed |

| Pre stretch ratio. | 250% and 200% manually, two-section variable (300% and 230% optional) |

| Stretch wrapping programs | 8 adjustable |

| Controller | PLC |

| Power - | |

| Supply | Single phase 240 V 50 Hz |

| Loading | 10A |

| Pallet Goods - | |

| Max size (length/width) | 1200X1000 mm |

| Max goods height incl. pallet | 2000 mm, Optional up to 3000 mm |

| Permitted load weight | 2000 kg |

| Stretch Film - | |

| Core diameter, max | 76 mm |

| Outer diameter, max | 250 mm |

| Film width, max | 500 mm |

| Film thickness | 9-35 my (standard is 0.012~0.023mm |

| Auto-function - | |

| Auto gripper for film end mounting | YES |

| Constancy temperature heater for film end welding | YES |

| Cutting wire for film cutting | YES |

| Remote control | YES (3 Sets) |

How does STRETCH WRAPPER: CST 205 works?

The operator loads the pallet on the turntable and starts the wrapping cycle with remote control or touch panel.

- At the end of the cycle the machine cuts the film and the arm wipes the tail-end against the load.

- The film remains connected in the film gripper. Ready to receive the next pack.

- The complete cycle will be done in automatic mode.

- The operator unloads the pallet manually.

- Easy change of all program parameters and settings with the new display. All functions can be manually operated such as film patterns and film tension. The chosen pre-stretch ratio stays constant, which guarantees a consistent low film consumption, load after load.

- Efficient Stretching Capability-The CST 205 stretch wrapper excels at securely stretching and wrapping palletized goods, maintaining product integrity throughout the supply chain while ensuring stability and minimizing product damage during transportation and storage.

- User Friendly Operation-The CST 205 stretch wrapper provides professionals in the packaging sector with a simple-to-use solution with user-friendly design. Operators can swiftly alter settings thanks to the machine's user-friendly control panel and pre-set wrapping programmes, which streamlines the packing process and saves time and effort.

- Versatile Wrapping Option-Businesses have access to flexible wrapping options with the CST 205 stretch wrapper, which can handle a range of load sizes and shapes. Its versatility in the packaging process, which eliminates the need for several machines or manual adjustments and enables effective packaging of a variety of products, comes from its capacity to accommodate varying pallet dimensions and irregularly shaped loads.These qualities make it a useful asset in the packaging sector, assisting companies to increase production, safeguard their goods, and guarantee a secure packaging procedure.

- Increased Efficiency-By automating the wrapping process, eliminating manual labour and time, and increasing productivity and throughput, the CST 205 stretch wrapper improves package efficiency.

- Cost Savings-The CST 205 stretch wrapper reduces product damage through secure wrapping, obviates the need for pricey repair or replacement, and lowers packing costs as a whole – use less film due to selectable pre-stretch ratio, (up to 1cm to 4cm – 300% or 1 film roll to be 4 film roll in term of actual useful length), less film consumption and more environmental friendly, saving firms money.

- Improved Load Stability-The CST 205 stretch wrapper improves load stability by firmly fastening goods to the pallet, lowering the possibility of movement or damage during transit, raising client satisfaction, and decreasing the possibility of product loss – thanks for selectable pre-stretch ratio to maximize the film’s bundling force, CST 205 can adapt to different quality of machine film.

- Versatility and Adaptability- Due of the versatility of the CST 205 stretch wrapper, a variety of products can be packaged effectively without the use of additional machines. This increases operational flexibility and streamlines the packaging process – thanks for advance film tension control system by analog sensor, stable film tension for different sizes and shapes of loads.

- Palletized Load Wrapping-It is frequently used in sectors including logistics, warehousing, and distribution centres to wrap palletized cargo, ensuring stability and protection during transportation and storage.

- Food and Beverage Industry-In the food and beverage business, pallets of packaged items are wrapped with stretch wrappers to maintain product integrity, hygiene, and effective packaging.

- Manufacturing and Production Facilities-It is employed in manufacturing and production facilities to properly package and safeguard finished items before shipping, expediting the procedure and guaranteeing the calibre of the final product.

- E-Commerce and Retail-The CST 205 stretch wrapper is essential to the e-commerce and retail sectors because it effectively packages and protects goods for shipping, ensuring that they reach customers safely.

- Load Placement- Place the palletized cargo onto the stretch wrapper's turntable, centering and balancing it to ensure stability during wrapping.

- Adjust Wrapping Parameters- Use the advanced control system to modify the wrapping parameters, such as tension, rotation speed, and film overlap, according to the demands of the particular load. This guarantees ideal adaptation for various load types.

- Start Wrapping Cycle- Use the relevant start button or the control panel to start the wrapping cycle. As the turntable spins, the wrapping head starts wrapping the load in film.

- Monitor and Inspect- Make sure the film is being wrapped securely and smoothly by keeping an eye on the process. To ensure correct wrapping, keep an eye on the work and make any required adjustments.

- Completion and Unloading- The film will be automatically cut and clamped to secure the load after the wrapping cycle is finished. The wrapped pallet should be carefully removed from the turntable before being stored or transported.

- Emergency Stop Button- The CST 205 stretch wrapper has an emergency stop button that lets users to quickly terminate the machine's operation in an emergency, protecting both users and bystanders.

- Overload Protection- The CST 205 stretch wrapper's overload protection features protect its internal workings, preserving the equipment's integrity and durability while lowering the possibility of breakdown or damage.

- Regular Cleaning- In order to prevent dust, debris, or film residue from building up, clean the machine frequently. Utilize cleaning products and equipment as directed by the manufacturer.

- Lubrication- Follow the lubrication instructions provided by the manufacturer, making sure that all moving parts and mechanisms are adequately greased to minimize wear and friction. Replace worn-out or damaged parts on a regular basis.

- Inspection and Adjustment- Conduct regular checks of all the parts, including the turntable, wrapping arm, control panel, and safety features, to look for any indications of damage or misalignment. If necessary, adjust and tighten any loose components.

- Film Roll Replacement- When the film roll is empty or broken, replace it. Make sure the film is loaded and positioned in the device according to the manufacturer's instructions.

- Training and Operator Awareness- Give operators the appropriate instruction on the safe use and upkeep of the CST 205 stretch wrapper. Operators should be encouraged to report any problems or anomalies right away.

- Service and Support- At Cyklop, we guarantee rock-solid service! Our central service center is manned by knowledgeable personnel who can offer expert advice and solutions over the phone. Our team of experienced technicians knows exactly what to do in any situation. To ensure efficiency, our service vans come equipped with the most commonly needed parts, enabling us to assist you promptly in almost all cases, allowing you to resume your operations without delay.