Introduction

Battery-operated tools are becoming increasingly popular across various industries, with battery-powered strapping tools leading the charge in the packaging sector. These tools, including cutting and sealing devices, are safer and easier to handle compared to their gas or corded counterparts. Many companies, particularly service providers in the packaging industry, are switching to these tools to prioritize worker safety. As industries evolve, the safety of workers remains a top priority. Traditional instruments such as gas or corded electric tools carry certain risks like electric shock, tripping, and dangerous emissions. In contrast, battery-powered strapping tools offer a modern alternative that drastically reduces these risks while enhancing effectiveness.

The Growing Popularity of Battery-Powered Tools

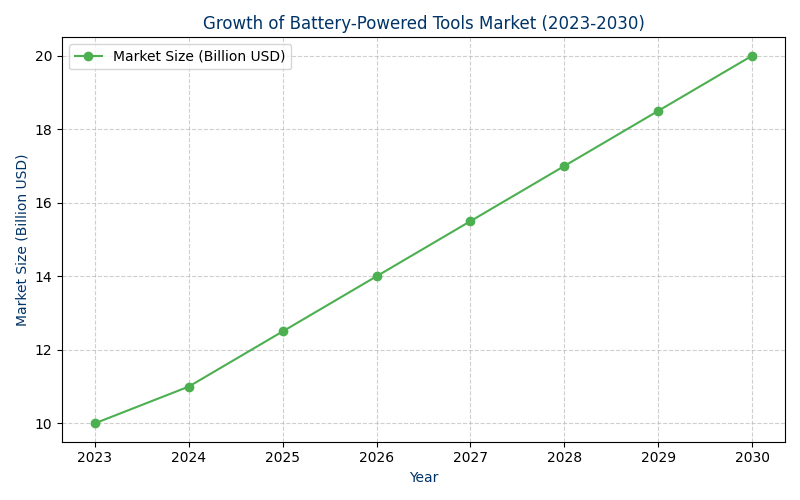

The makeover of packaging equipment is perhaps the most significant change taking place today, as companies seek tools that are safe, efficient, and eco-friendly. Battery-powered tools, particularly strapping machines, provide an excellent solution with numerous advantages. These include lower noise levels, cordless operation, and higher packaging productivity.

Battery-powered tools, including strapping tensioners and strapping sealers, are also widely used in other industries such as construction, logistics, and manufacturing. Lithium battery technology has improved to the point that strapping tools are extremely powerful and dependable, giving them the ability to perform heavy-duty work. The integration of brushless DC motors has further enhanced their performance and longevity. Additionally, regulations aimed at reducing carbon emissions and ensuring worker safety are forcing companies to replace conventional equipment with cleaner battery-operated equipment like semi-automatic and fully automatic strapping machines.

Benefits of Battery-Powered Tools

Battery-powered tools, especially those used for sealing and strapping, offer numerous benefits over traditional equipment. These advantages extend beyond safety, impacting efficiency, cost savings, and environmental sustainability.

| Benefit | Details |

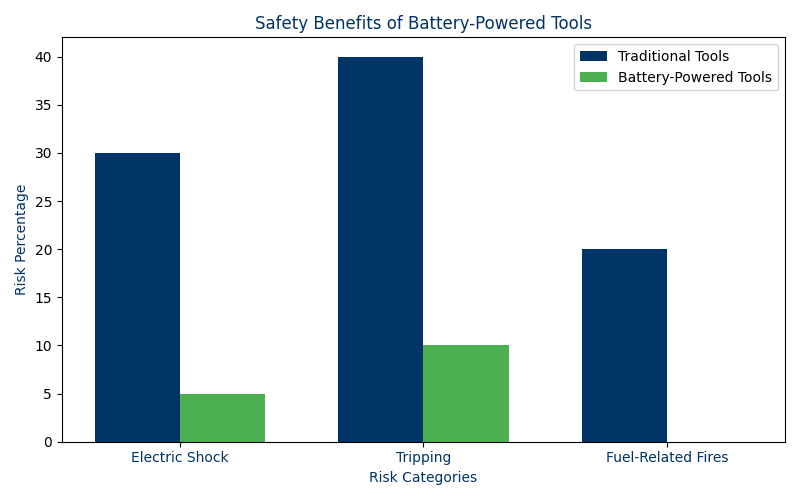

| Safer to Use | No cords mean fewer trips and falls. No risk of electric shock. Eliminates the danger of fuel-related fires and explosions. |

| Easier to Handle | Lightweight and comfortable to use. Reduces strain on workers. Allows for longer usage without fatigue. |

| Better for the Environment | No gas means no harmful fumes. Less noise pollution. Helps companies comply with environmental regulations. |

| Saves Money | Lower maintenance costs. No need to buy fuel. Lasts longer than gas-powered tools. Reduces downtime due to fewer mechanical failures. |

| Increased Productivity | Faster startup times. No need to refuel or warm up. Workers can complete tasks more efficiently, improving overall packaging productivity. |

| Enhanced Durability | Fewer moving parts mean less wear and tear. Strapping tools made with mild steel components offer increased longevity. |

Why Companies Choose Battery-Powered Tools

Businesses recognize the value of battery-powered tools, such as strapping machines and strapping tensioners, in improving operations and reducing risks.

| Feature | Benefits |

| Portable and Flexible | No need for power outlets. Works well in large spaces and outdoor areas. Ideal for remote job sites where electricity is limited. |

| Reliable Power | Lithium batteries provide steady performance. Capable of handling demanding tasks without power fluctuations. |

| Smart Features | Some tools have digital controls and PLC control systems. Automatic shutoff for safety. Integration with IoT technology for performance tracking. Battery indication features help monitor power levels. |

| User-Friendly Design | Simple operation reduces training time. Ergonomic designs reduce worker fatigue. |

| Weather-Resistant | Many models are designed to function in extreme temperatures and harsh environments. |

Industry Events Showcasing These Tools

Numerous events showcase only the latest battery-powered equipment for new applications that businesses are creating as a result of technological innovations. These expos highlight trends and create opportunities for companies to test entirely new equipment, including advanced strapping tools and machines.

- PACK EXPO – Packaging and material handling; automated and battery-operated strapping machines.

- Interpack – New trends in packaging technology, such as sustainable and energy-efficient tools, including battery-powered strapping tools.

- MODEX – Innovations include an increasing emphasis on battery power, showcasing advancements in strapping machines and strapping tensioners.

- Supply chain and automation events become increasingly important. Attending these events allows business owners and industry professionals to explore new products, network with experts, and make informed purchasing decisions about battery-powered strapping tools and other packaging equipment.

How These Tools Improve Workplaces

The impact of battery-powered tools, particularly strapping machines and strapping sealers, extends beyond individual benefits—they contribute to a safer, more efficient work environment.

- Worker safety improves considerably due to fewer trip hazards, no fuel emissions hazards, and relatively less electric shock hazards.

- Higher productivity is promoted by offering quick startup time and fewer chances of mechanical glitches, which keeps workers occupied with task completion for longer periods.

- Operational costs reduce with lower fuel, maintenance, and tool replacement expenses.

- Easier regulatory compliance with safety and environmental standards for businesses using battery-powered equipment.

- Workplace morale improves as employees use tools that are quieter and ergonomically better, thus increasing employee satisfaction.

- Future Innovations – AI-enabled tools, solar-powered options, and faster-charging batteries are on the horizon, promising even greater advancements in strapping and sealing technology.

Conclusion

The adoption of Battery powered tools, especially in the realm of strapping and sealing, has introduced significant changes in the industry, replacing old types of equipment with much safer and more efficient alternatives. The benefits of battery-powered strapping tools extend beyond worker safety to long-term cost savings, improved worker productivity, and environmental advantages. This technology continues to evolve, with advancements in friction sealing technology, automatic tensioning, and one-touch operation enhancing sealing efficiency and ease of use.

As the industry progresses, we can expect to see further innovations in battery-powered strapping tools, including improvements in tensioning force, strap width compatibility, and the ability to work with various materials such as PET straps, PP straps, and polypropylene straps. These advancements will cater to diverse packaging needs, from light-duty strapping applications to heavy-duty box strapping operations.

Businesses transitioning to battery-powered tools should be encouraged to explore trade shows and industry events to learn more about safety improvements, sealing efficiency enhancements, and the latest developments in strapping machine technology. By staying informed and adopting these innovative tools, companies can significantly boost their packaging productivity while ensuring a safer, more efficient workplace. The future of packaging lies in the continued development of battery-powered strapping tools, with features like adjustable strap thickness settings and improved strapping rolls management, further enhancing the efficiency and versatility of these essential tools.